홈 > HookDrive > Information

HookDrive™ is a next-generation index drive with a unique hook mechanism that does not use gears. It provides precise split rotation and instantaneous stopping without any backlash. This mechanism eliminates mechanical slack and wear factors compared to existing gear-based drive systems, greatly improving repeat positioning accuracy and durability. It maintains stable performance even in long-term high-load and high-frequency operating environments.

In particular, in the field of industrial automation, it was necessary to adopt a complex gear structure to implement a rotary drive in a narrow space. However, the HookDrive™ uses a simplified hook-based indexing structure that enables rotation without gears, allowing for minimal installation space and lightweight construction while delivering high torque and precision. This design provides excellent applicability in industrial equipment with limited space or in small-sized, high-density equipment environments.

The product is available in CW, CCW, and bidirectional models, and allows for 15° incremental rotation. Users can set the number of divisions according to their needs. The maximum output torque is in the range of 1.8 to 3.0 Nm, making it suitable for small and medium-sized industrial automation equipment. The drive can be operated using a standard pneumatic system with a pressure of 1.0 MPa or a DC 24V motor, allowing for flexible application depending on the equipment environment and control method.

The structure applies a compact and lightweight design to minimize installation space constraints and incorporates a digital display and integrated control board to facilitate monitoring of operating conditions, setting division angles, and maintenance tasks. The control method provides NC (controller not applied) or C (controller applied) types, and the user can select the pneumatic or motor drive option as needed.

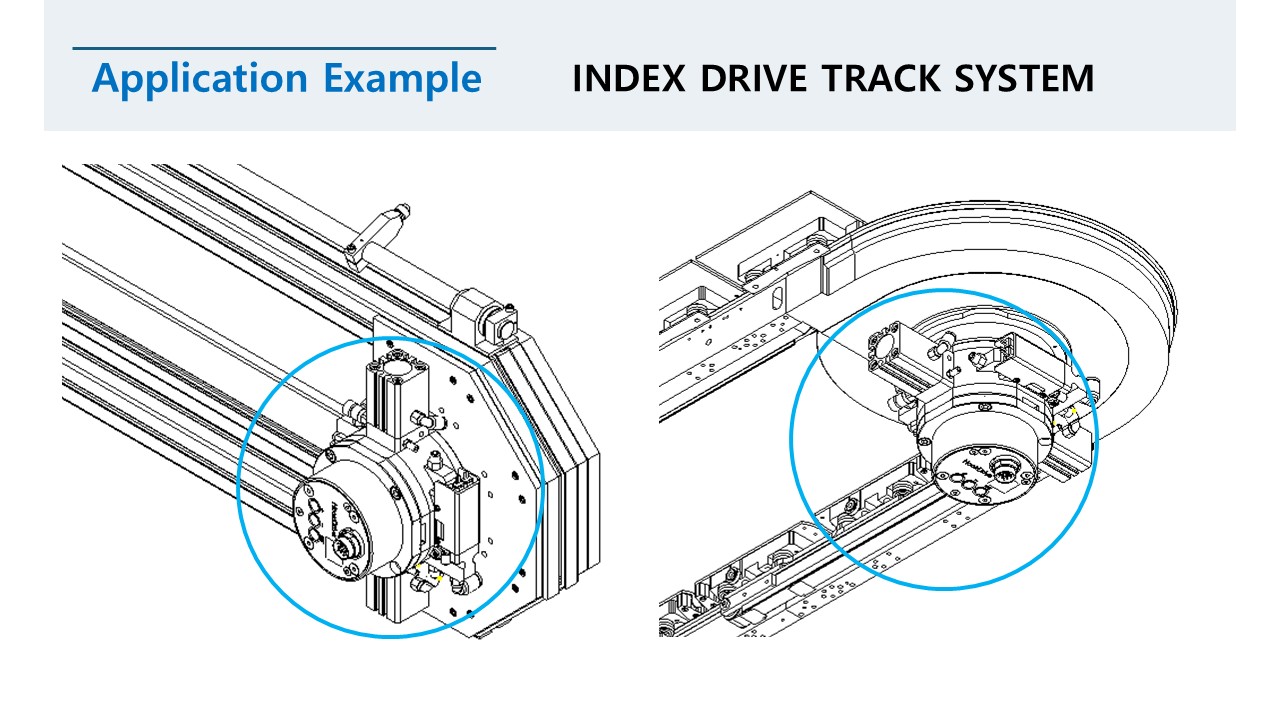

▪️This is an example of a Hook drive applied to a tracking system.

▪️It shows a representative example of how to use the splitting angle in tracking systems.

▪️It provides sufficient space and torque for efficient application.

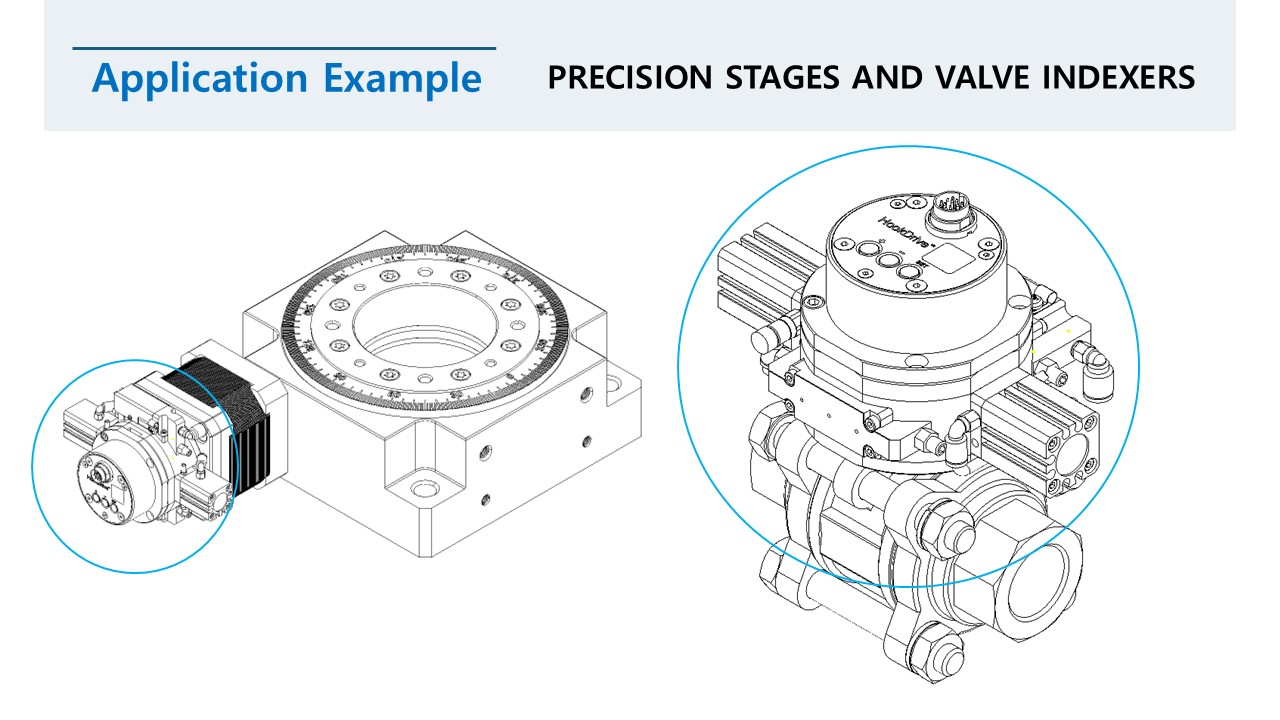

▪️This device is an example of a precision stage and valve indexer.

▪️With high resolution and excellent precision, it controls the valve flow precisely and stably.

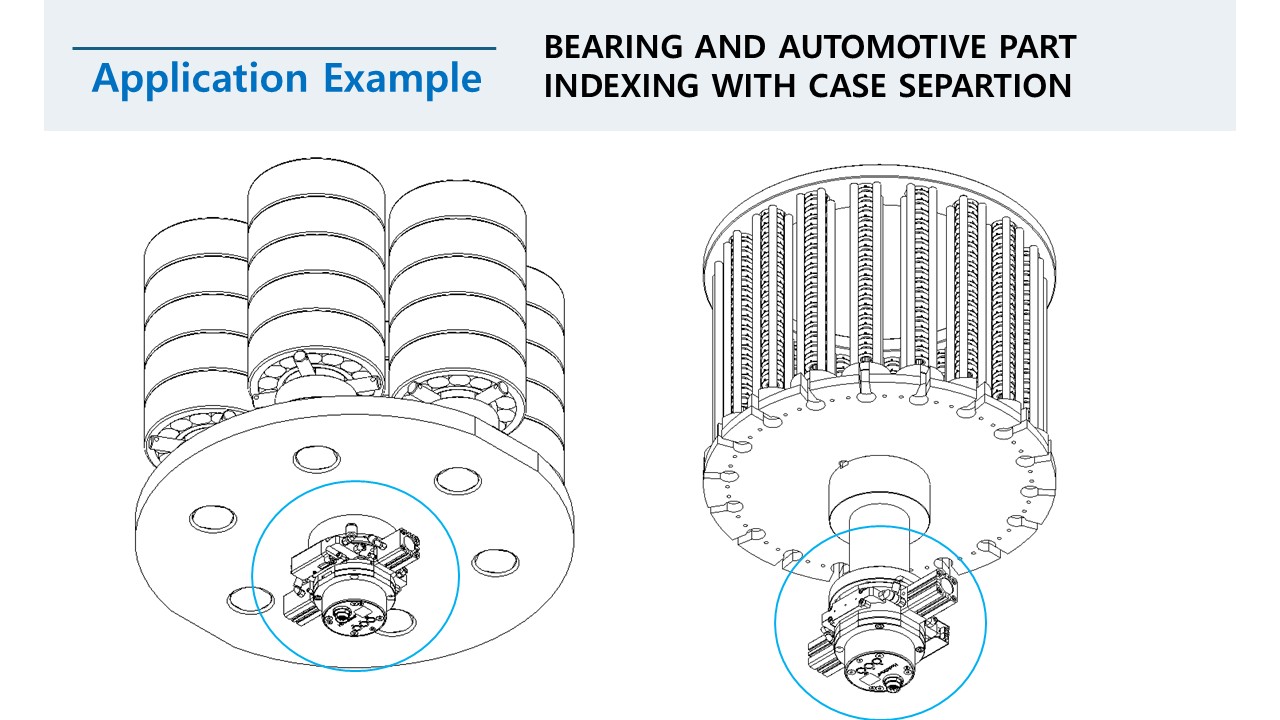

▪️This device is placed below the bearing indexer to control the split angle.

▪️There are various ways to apply the division angle in the processing and assembly of automobile parts, and doing so can help create an efficient automated process.

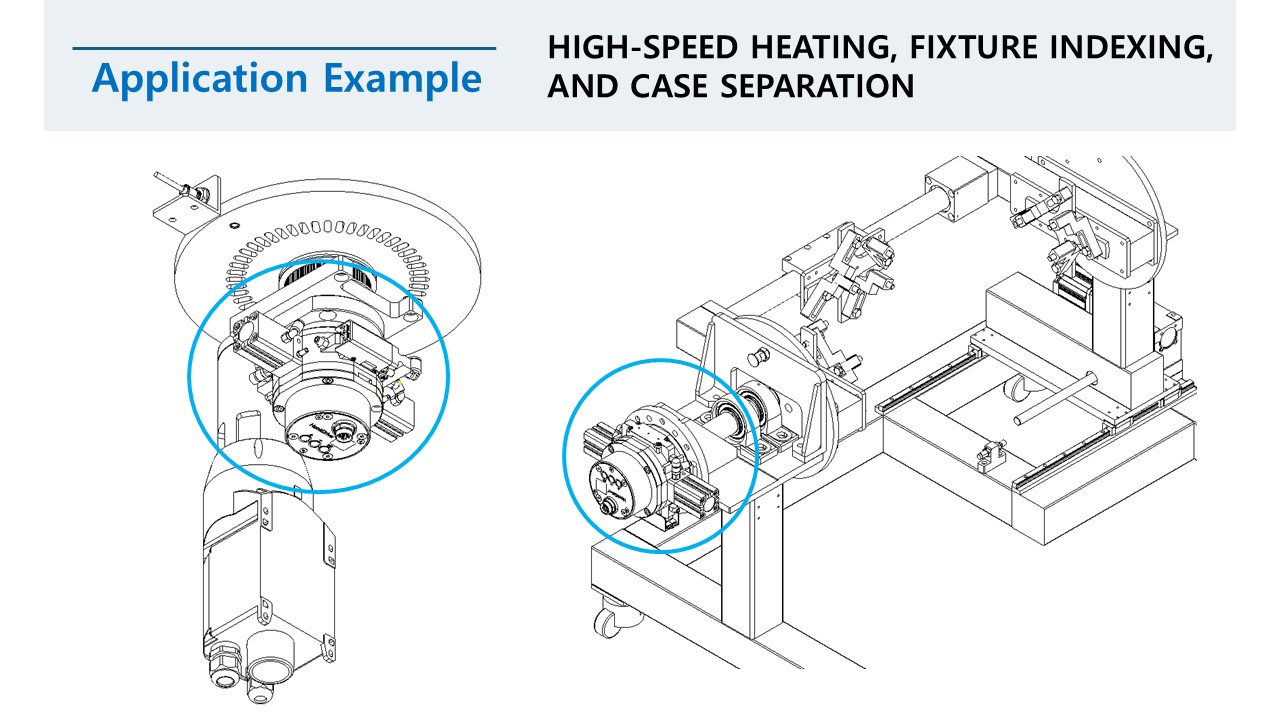

▪️This case study illustrates the application of indexing division for high-speed heating processes.

▪️Additionally, you can increase the efficiency of the process by using the Hook drive to adjust the rotation angle of the automatic jig.