홈 > WiMAS > Information

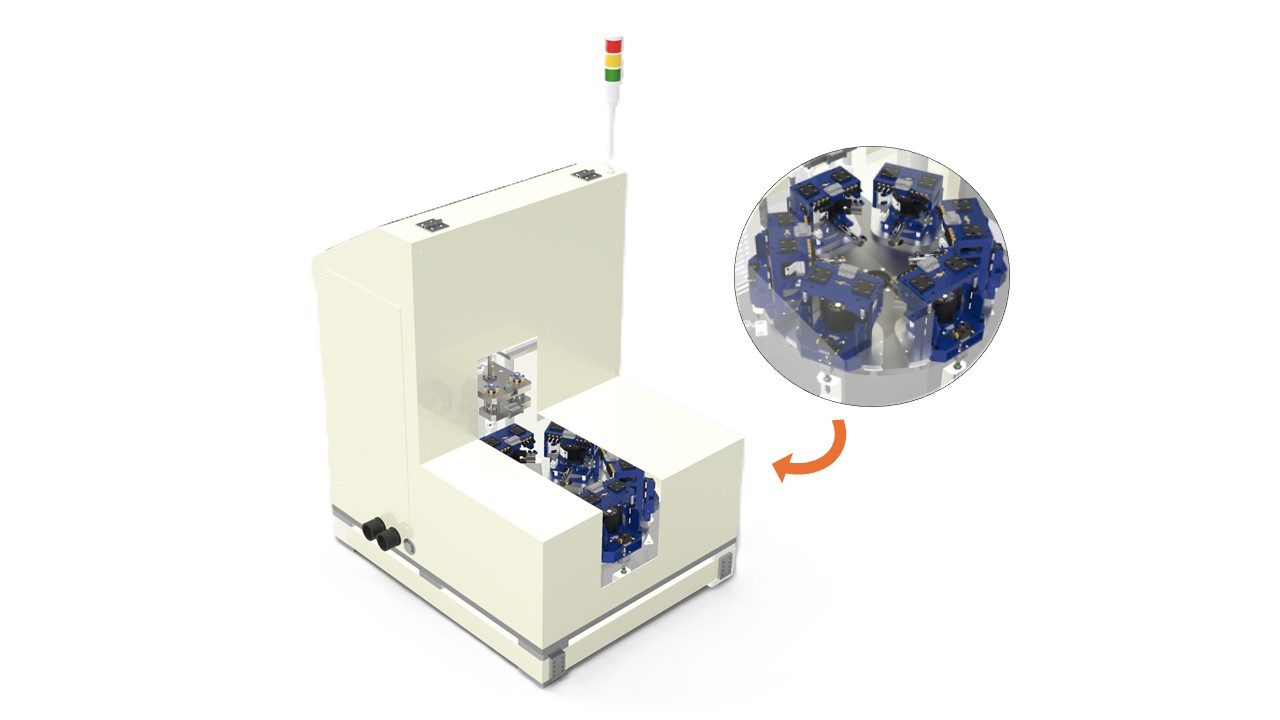

The Hookdrive WiMAS is a new solution that overcomes the structural limitations of existing automated screwdrivers. In particular, while German robot-based fastening systems can only work at fixed angles and take 68 seconds to fasten a single screw, this device can fasten M1.5-M4 grade small screws in approximately two seconds.

The existing pneumatic shooting system has several limitations in terms of precision and work time. The three-step process of nut distribution, transport, and fastening causes cumulative errors and defect rates, and takes approximately 96 seconds for 12 fasteners. In contrast, the Hookdrive system uses a free-fall-based screw distribution mechanism and a multi-angle screw driving structure to significantly improve screw driving stability and position flexibility.

It operates without vacuum, air pressure, or suction and can be locked in any direction, solving the fundamental problems of existing equipment, such as screw self-standing failure, friction resistance, and misalignment. It is a device that satisfies the important elements of "time" and "accuracy" in automated equipment. Additionally, a single magazine can hold more than 24 screws, allowing for high-efficiency continuous operation. It eliminates the need for a separate screw distribution device, providing space savings and installation flexibility. This design improves durability and makes maintenance easier.